Electrical Equipment

VFDs/VSDs

A variable-frequency drive (VFD) (also termed adjustable-frequency drive, variable speed drive, AC drive, micro drive or inverter drive) is a type of adjustable-speed drive used in electro-mechanical drive systems to control AC motor speed and torque by varying motor input frequency and voltage. VFDs are used in applications ranging from small appliances to the largest of mine mill drives and compressors.

However, around 25% of the world's electrical energy is consumed by electric motors in industrial applications, which are especially conducive for energy savings using VFDs in centrifugal load service and VFDs' global market penetration for all applications is still relatively small. That lack of penetration highlights significant energy efficiency improvement opportunities for retrofitted and new VFD installations.

Over the last four decades, power electronics technology has reduced VFD cost and size and has improved performance through advances in semiconductor switching devices, drive topologies, simulation and control techniques, and control hardware and software.

VFDs are available in a number of different low- and medium-voltage AC-AC and DC-AC topologies.

Soft Starters

A motor soft starter is a device used with AC electrical motors to temporarily reduce the load and torque in the power train and electric current surge of the motor during start-up. This reduces the mechanical stress on the motor and shaft, as well as the electrodynamic stresses on the attached power cables and electrical distribution network, extending the lifespan of the system.

It can consist of mechanical or electrical devices, or a combination of both. Mechanical soft starters include clutches and several types of couplings using a fluid, magnetic forces, or steel shot to transmit torque, similar to other forms of torque limiter. Electrical soft starters can be any control system that reduces the torque by temporarily reducing the voltage or current input, or a device that temporarily alters how the motor is connected in the electric circuit.

Soft starters can be set up to the requirements of the individual application. In pump applications, a soft start can avoid pressure surges. Conveyor belt systems can be smoothly started, avoiding jerk and stress on drive components. Fans or other systems with belt drives can be started slowly to avoid belt slipping. Soft starts are seen in electrical R/C helicopters, and allow the rotor blades to spool-up in a smooth, controlled manner rather than a sudden surge. In all systems, a soft start limits the inrush current and so improves stability of the power supply and reduces transient voltage drops that may affect other loads.

MCC Panel

A motor control center (MCC) is an assembly of one or more enclosed sections having a common power bus and principally containing motor control units. Motor control centers are in modern practice a factory assembly of several motor starters. A motor control center can include variable frequency drives, programmable controllers, and metering and may also be the electrical service entrance for the building.

Motor control centers have been used since 1950 by the automobile manufacturing industry which used large numbers of electric motors. Today they are used in many industrial and commercial applications. Where very dusty or corrosive processes are used, the motor control center may be installed in a separate air-conditioned room, but often an MCC will be on the factory floor adjacent to the machinery controlled.

A motor control center consists of one or more vertical metal cabinet sections with power bus and provision for plug-in mounting of individual motor controllers. Very large controllers may be bolted in place but smaller controllers can be unplugged from the cabinet for testing or maintenance.

Panel / Distribution Board

A distribution board (also known as panel board, breaker panel, or electric panel) is a component of an electricity supply system that divides an electrical power feed into subsidiary circuits, while providing a protective fuse or circuit breaker for each circuit in a common enclosure. Normally, a main switch, and in recent boards, one or more residual-current devices (RCD) or residual current breakers with overcurrent protection (RCBO), are also incorporated.

Local Control Station

Local Control Stations (LCS) give you the choice of using remote process control signals for the equipment’s or operating the equipment at the location of your choice, either at the equipment or just nearby. The control elements can also be mounted on a mounting rail or in the front wall. Free installation areas can be designated for the subsequent installation of our control and signaling devices, which are then, sealed using blanking plugs. All explosion-protected local control stations are supplied prewired on terminals.

Control Panel Components

Electrical control panel is a cabinet which contains electrical components to control various types of devices. Components include contactors, relays, OLR, circuit breakers, fuses, isolators, indication lamps, selector switches, push buttons, transformers, E-stop, timers, voltmeter, ammeter, display etc. Electrical control panels are used in all production lines Such as in factories to monitor and control machines or production lines. Older control panels are most often equipped with push buttons and analog instruments, whereas today in many cases HMI are used for monitoring and control purposes.

AC & DC Motors

While both A.C. and D.C. motors serve the same function of converting electrical energy into mechanical energy, they are powered, constructed and controlled differently. The most basic difference is the power source. A.C. motors are powered from alternating current (A.C.) while D.C. motors are powered from direct current (D.C.), such as batteries, D.C. power supplies or an AC-to-DC power converter. D.C wound field motors are constructed with brushes and a commutator, which add to the maintenance, limit the speed and usually reduce the life expectancy of brushed D.C. motors. A.C. induction motors do not use brushes; they are very rugged and have long life expectancies. The final basic difference is speed control. The speed of a D.C. motor is controlled by varying the armature winding’s current while the speed of an A.C. motor is controlled by varying the frequency, which is commonly done with an adjustable frequency drive control.

Power Supply Units

A power supply is an electronic device that supplies electric energy to an electrical load. The primary function of a power supply is to convert one form of electrical energy to another and, as a result, power supplies are sometimes referred to as electric power converters. DC power supply provides the required level of DC power to the load using an AC supply at the input. Input transformer is used to transform the incoming line voltage down to the required level for the power supply. Typically the input transformer provides a step down function. The advantage of the DC supply is greater efficiency because the switching transistor dissipates little power when acting as a switch. Other advantages include smaller size and lighter weight from the elimination of heavy line-frequency transformers, and lower heat generation due to higher efficiency.

Cables & Wires

A cable is two or more wires running side by side and bonded, twisted, or braided together to form a single assembly. The term originally referred to a nautical line of specific length where multiple ropes, each laid clockwise, are then laid together anti-clockwise and shackled to produce a strong thick line, resistant to water absorption, that was used to anchor large ships. In electrical engineering cables are used to carry electric currents. An optical cable contains one or more optical fibers in a protective jacket that supports the fibers. We offer Electrical, Instrumentation, Fibre optic, Ethernet cables - Flame retardant/fire resistance, low voltage, Cu/XLPE etc., for industrial applications

Solar Green Energy

Solar energy is radiant light and heat from the Sun that is harnessed using a range of ever-evolving technologies such as solar heating, photovoltaics, solar thermal energy, solar architecture and artificial photosynthesis. It is an important source of renewable energy and its technologies are broadly characterized as either passive solar or active solar depending on how they capture and distribute solar energy or convert it into solar power. Solar panel refers to a panel designed to absorb the sun's rays as a source of energy for generating electricity or heating. A single solar module can produce only a limited amount of power; most installations contain multiple modules. A photovoltaic system typically includes a panel or an array of solar modules, a solar inverter, and sometimes a battery and/or solar tracker and interconnection wiring.

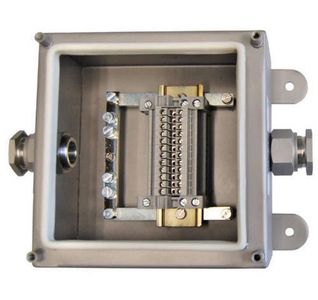

Junction Boxes

An electrical junction box is a container for electrical connections, usually intended to conceal them from sight and deter tampering. A small metal or plastic junction box may form part of an electrical conduit or thermoplastic-sheathed cable (TPS) wiring system in a building. Junction boxes form an integral part of a circuit protection system where circuit integrity has to be provided, as for emergency lighting or emergency power lines, or the wiring between a nuclear reactor and a control room. In such an installation, the fireproofing around the incoming or outgoing cables must also be extended to cover the junction box to prevent short circuits inside the box during an accidental fire

Industrial Lightings & Luminaries

A light fixture or luminaire is an electrical device used to create artificial light by use of an electric lamp. All light fixtures have a fixture body and a light socket to hold the lamp and allow for its replacement. Fixtures may also have a switch to control the light. We have a dedicated range of solutions, designed to meet the requirements of renewable energy installations. Our range of luminaires for the renewable market combine the robust design to meet the high levels of ingress protection and resistance to corrosive saline conditions required for offshore substations or unmanned platforms. Zone1&2 luminaries are available.

Accessories

We sell cable glands, trays, conduit, channels, multi cable transit, hose and ladder etc.,

Available for Zone1 & Zone2 applications.

ATEX/IECEx/IS/NEC equipment.

We sell Ex certified equipment for classified areas applications.

SIEMCAS Innovative Solutions Pvt Ltd

India

Phone no. +91 9791718664

Email ID: info@siemcas.com / siemcas@yahoo.com / siemcas@outlook.com

Copyright © 2025 SIEMCAS - All Rights Reserved.

This website uses cookies.

“This website collects cookies to deliver better user experience” “We collect cookies to analyze our website traffic and performance; we never collect any personal data” “Cookies help us display personalized product recommendations and ensure you have great shopping experience”